Equipment of Flue Gas Denitration

Flue gas desulfurization and denitration technology is a boiler flue gas purification technology applied to the chemical industry of multi nitrogen oxide and sulfur oxide generation. Nitrogen oxides and sulfur oxides are one of the main sources of air pollution. Therefore, the application of this technology has many benefits for ambient air purification. Known flue gas desulfurization and denitration technologies include pafp, ACFP, pyrolusite method, electron beam ammonia method, pulse corona method, gypsum wet method, catalytic oxidation method, microbial degradation method and so on.

Instruction

Primary heating, iron and metallic groups and thermal strength plant life in city wintry weather are large-scale coal-fired manufacturing, which has come to be the supply of air pollutants. in latest years, all localities have followed lively environmental protection guidelines. in mixture with the actual situation of coal-fired production, the countrywide environmental safety department, on the only hand, publications companies to enforce coal to fuel projects, allows coal-fired groups to use herbal gas easy power, reduces the emission of coal-fired waste gas and improves air exceptional; then again, it is also the number one element. for maximum huge coal-fired corporations that do not have the conditions to transform coal to gas, they are actively guided and supported to sell using soot elimination and desulfurization and denitration gadgets and gadget, just so the emission of risky soot and dangerous gases in the air has been nicely managed.

In practice, it is found that due to the installation of dust removal and desulfurization and denitration equipment in the chimney, the natural emission of the chimney increases the resistance, which affects the normal production of enterprises. After some enterprises install and use the dust removal and sulfur removal equipment, in order to meet the smoke exhaust effect of the chimney, they add blowers and other related equipment, so that the production cost continues to increase. Enterprises have a negative attitude towards the promotion and use of these environmental protection processes and technologies, and are not active in the maintenance and improvement of equipment. The dust removal and sulfur removal process has increased resistance to varying degrees in the process of promotion and use, which needs to be solved by taking positive measures.

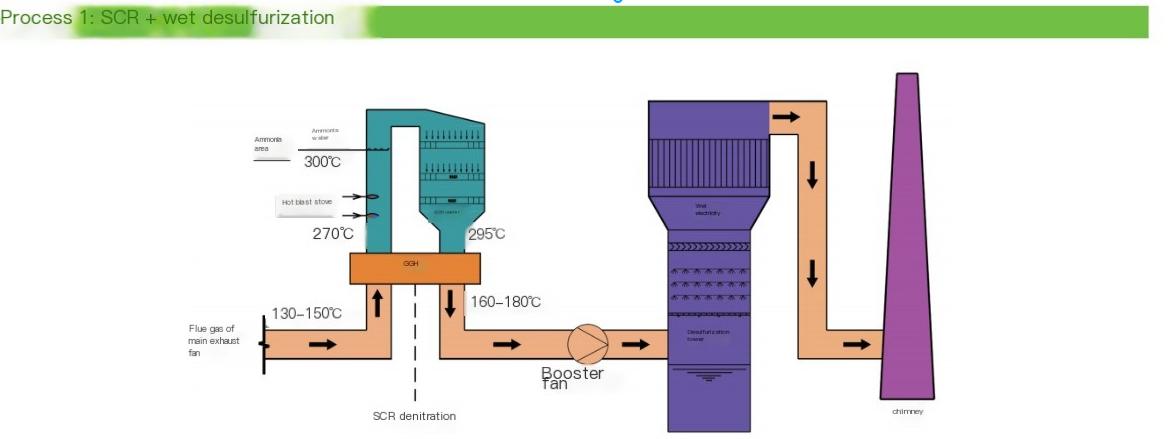

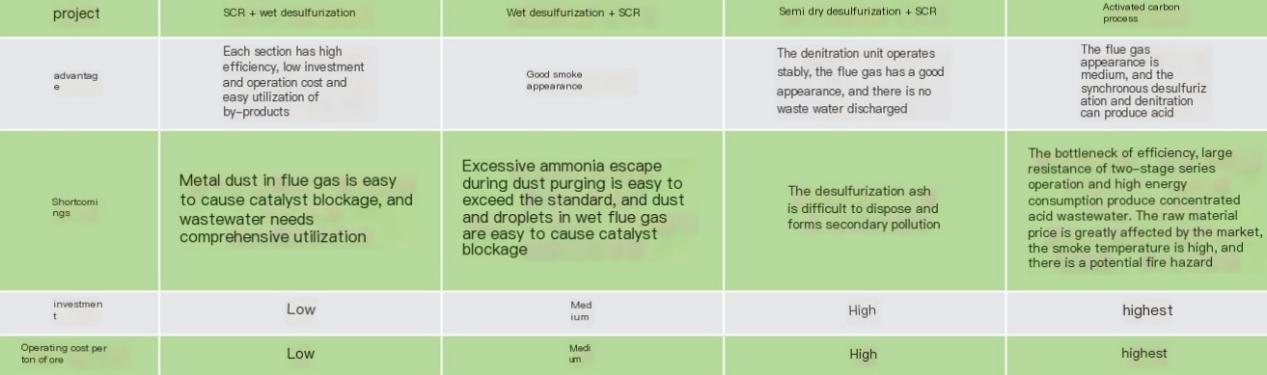

Process

Specification

In view of the difficulties and various problems existing in coal-fired enterprises in popularizing and using the integrated dust and sulfur removal process technology, it is necessary to optimize the working ideas of technical process promotion, improve the ideological understanding of enterprises, solve the technical problems in the use process, and enhance the action force of coal-fired enterprises in using environmental protection technology. First, renew ideas and unify understanding. Whether thermal power enterprises or steel smelting and processing enterprises, their production purpose is not only to increase benefits for enterprises, but also to provide products and services to meet the needs of life for the society. Therefore, we should try to solve the problems caused by the application of dust removal and desulfurization and denitration process units and equipment in production, and take corresponding technical measures to meet the needs of chimney emission. Second, do a good job in the recycling of waste, offset the increased investment in dust removal equipment and reduce production costs. As an important part of dry flue gas desulfurization, electron beam flue gas desulfurization technology has been widely used in desulfurization. The application of this equipment can not only effectively reduce the waste of pollution sources, but also be used as organic fertilizer.

Related News

Submitted successfully

We will contact you as soon as possible