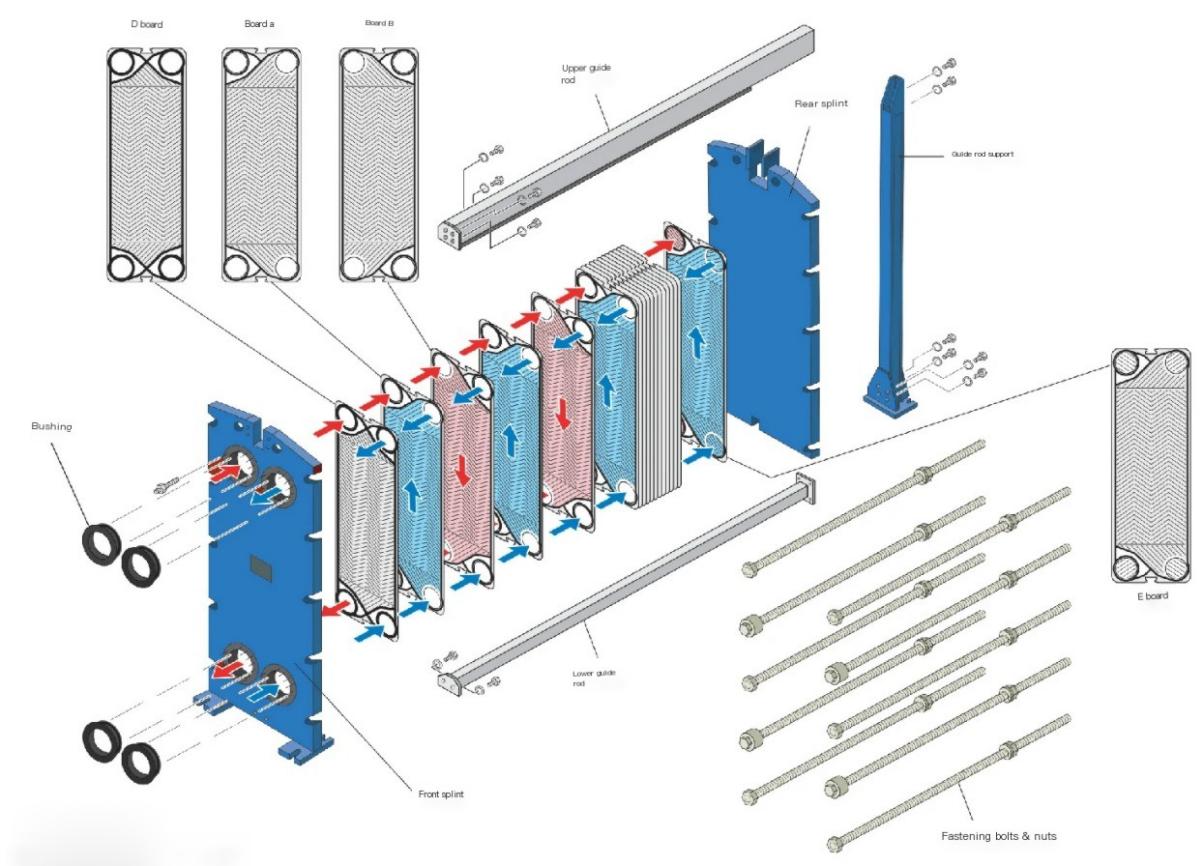

Completed Heat Plate Exchanger

Plate heat exchanger is a kind of high-efficiency heat exchanger which is composed of a series of corrugated metal sheets. Thin rectangular channels are formed between various plates for heat exchange. Plate heat exchanger is an ideal equipment for liquid-liquid and liquid vapor heat exchange.

Introduce

Plate heat exchanger has the characteristics of excessive warm temperature alternate ordinary performance, small warmth loss, compact and light-weight shape, small ground region, massive software and extended provider life. beneath the same strain loss, its warmth switch coefficient is three-5 times better than that of tubular warmth exchanger, the floor region is one 1/3 of that of tubular warmth exchanger, and the warmth recovery charge can be greater than 90%.

Structural principle

The detachable Plate heat exchanger is made up of many corrugated thin plates stamped at a certain interval, sealed around by gaskets, and overlapped and compressed by the frame and compression screws. The four corner holes of the plate and gasket form the fluid distribution pipe and collection pipe. At the same time, the cold and hot fluids are reasonably separated to make them flow in the flow channels on both sides of each plate, and heat exchange is carried out through the plate.

Basic composition structure

1. Plate of plate heat exchanger and sealing gasket of plate heat exchanger

2. Fix the pressing plate

3. Movable pressing plate

4. Clamping bolt

5. Upper guide rod

⒍ lower guide rod

⒎ rear column

Application area

Plate heat exchanger has been widely used in metallurgy, mining, petroleum, chemical industry, electric power, medicine, food, chemical fiber, papermaking, light textile, shipping, heating and other departments. It can be used for heating, cooling, evaporation, condensation, sterilization and disinfection, waste heat recovery and other situations.

Solar energy utilization: participate in the heat exchange process of heat transfer medium ethylene glycol and other antifreeze in the solar collector plate, so as to achieve the purpose of using solar energy.

Chemical industry:manufacturing titanium oxide, alcohol fermentation, synthetic ammonia, resin synthesis, manufacturing rubber, cooling phosphoric acid, cooling formaldehyde water, alkali carbon industry, electrolytic alkali production.

Iron and steel industry: cooling quenching oil, cooling electroplating liquid, cooling reducer lubricating oil, cooling rolling machine, wire drawing machine coolant.

Metallurgical Industry: heating and cooling of aluminate mother liquor, cooling of sodium aluminate, cooling of lubricating oil of aluminum mill.

Machinery manufacturing: all kinds of quenching liquid cooling, cooling press, industrial mother machine lubricating oil, heating engine oil.

Food industry:Salt making, sterilization and cooling of dairy products, soy sauce and vinegar, heating and cooling of animal and vegetable oil, heating and cooling of beer and wort in beer production, sugar making, gelatin concentration, sterilization and cooling, and manufacturing of sodium glutamate.

Textile industry: heat recovery of various waste liquid, cooling of boiling phosphating fiber, cooling of viscose, cooling of acetic acid and acetic anhydride, cooling of alkaline aqueous solution, heating and cooling of viscose filament.

Paper industry: cooling of black water, heating and cooling of salt and alkali liquor for bleaching, heat recovery of waste glass paper, heating of cooking acid, cooling of sodium hydroxide aqueous solution, recovery of waste bleaching paper, condensation of exhaust gas, preheating and concentration of waste liquid like pulp.

Central heating:Waste heat of thermal power plant, district heating, heating domestic water, boiler district heating.

Oil industry: heating and cooling synthetic detergent, heating whale oil, cooling vegetable oil, cooling sodium hydroxide, cooling glycerol and emulsified oil.

Power industry: generator shaft pump cooling, transformer oil cooling.

Ships: diesel engine, central cooler, jacket water cooler, piston cooler, lubricating oil cooler, preheater, seawater desalination system (including multi-stage and single-stage).

Related News

Submitted successfully

We will contact you as soon as possible