Prefabricated Office Building

We have a sound system of qualifications, the existing steel structure engineering contracting qualification (Level I), steel structure manufacturing and installation qualification (Level I), light steel structure engineering design qualification (Grade A), mechanical and electrical construction general contracting qualification (Level I), environmental engineering contracting qualification (Level I) etc., in total with 20 qualifications.

Basic Instruction

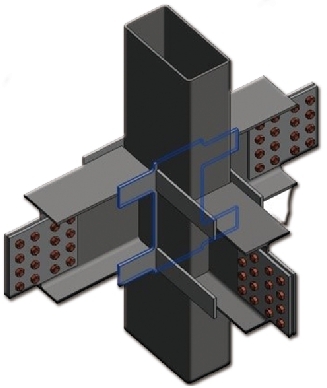

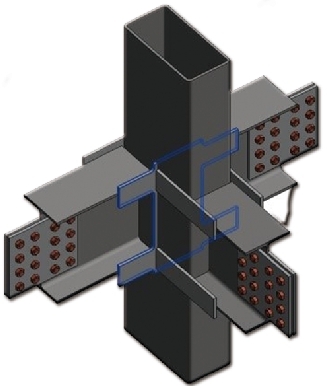

Our green assembled steel structure technology system uses improved node connection technology. We fully take into account the requirements of residential functions and easy decoration in this limited space of the house, and there is no longer the traditional steel structure and some concrete structure of the convex beam phenomenon. After the optimization and innovation node, the connection method and production process are easy to control the quality of technology.

Steel construction project

Characteristics of our Assembled Steel Structure Technology System

1. Anti-corrosion

Our company adopts advanced steel structure anti-corrosion processing technology. After the surface sandblasting, the primer coating is sprayed immediately. The surface treatment and primer interval time should not exceed 30 seconds and the film adhesion is strong. Different components can be sprayed with different film thickness of the primer to meet the anti-corrosion requirements, immediately after the primer into the drying room drying, drying room at about 70 ℃, the paint quickly reach the finger dry state.

2. High efficiency sound insulation

The use of self-compacting concrete column beam pouring, forming a closed entity, can effectively cut off the transmission of sound.

3. Fire protection

Method one: The use of fire protection coating, which is specially used to spray the surface of steel components, can form a fire-resistant insulation to improve the fire resistance of steel.

Method two: The outer cladding made of thick plate or sheet is adopted for fire prevention, which commonly use gypsum board, cement vermiculite board, calcium silicate board etc. as the raw material. The plate can isolate the direct contact between steel and flame to achieve fire prevention and protection.

Method three: H-shape beam adopts packaging method for fire protection, that is, isolating the direct contact of the flame and steel

Related News

Submitted successfully

We will contact you as soon as possible