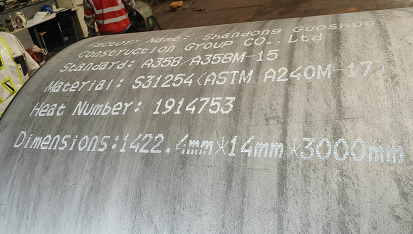

S31254 Special Stainless Steel Penstock

1. a large number of field experiments and extensive use experience show that unss31254 has high crevice corrosion resistance in seawater even at slightly higher temperatures, and only a few kinds of stainless steels have this performance.

2. the corrosion resistance of unss31254 in acid solutions and oxidizing halide solutions such as those required for paper bleaching production can be compared with that of nickel base alloys and titanium alloys with the strongest corrosion resistance.

3. because unss31254 has high nitrogen content, its mechanical strength is higher than that of other types of austenitic stainless steel. In addition, unss31254 has high ductility, impact strength and good weldability.

4. the high molybdenum content of unss31254 can make it have a higher oxidation rate during annealing, so it has a rougher surface than ordinary stainless steel after pickling. However, this has no adverse effect on the corrosion resistance of the steel.

The high content of molybdenum, chromium and nitrogen make unss31254 have excellent resistance to pitting corrosion and crevice corrosion. The addition of copper improves the corrosion resistance in some acids. In addition, unss31254 has good stress corrosion cracking resistance due to its high nickel content and high chromium and molybdenum content.

S31254 is an alloy material with corrosion resistance. Its density is 8.0g/cm3 and its melting point is 1320-1390 ℃. The carbon content of unss31254 is very low, which means that the risk of carbide precipitation due to heating is very small. The steel can pass Strauss intergranular corrosion test (strausstestastma262 regulation E) even after one hour sensitization treatment at 600-1000 ℃. However, due to the high alloy content of the steel. In the above temperature range, the metal mesophase may precipitate on the grain boundary. These precipitates do not pose a risk of intergranular corrosion when the steel is used in corrosive media. Therefore, welding can be carried out without intergranular corrosion. However, in hot concentrated nitric acid, these precipitates may cause intergranular corrosion in the heat affected zone. In solutions containing chloride, bromide or iodine ions, ordinary stainless steels will be immediately eroded by local corrosion in the form of pitting corrosion, crevice corrosion or stress corrosion cracking. However, in some cases, the presence of halides can accelerate uniform corrosion. This is especially true when halides are present in non oxidizing acids. In pure sulfuric acid, 254SMO has much greater corrosion resistance than 316 ordinary stainless steel. However, the corrosion resistance of unss31254 is slightly weaker than that of 904L (no8904) stainless steel at high concentration. In sulfuric acid containing chloride ions, unss31254 has the greatest corrosion resistance. Since local corrosion and uniform corrosion may occur, 316 ordinary stainless steel cannot be used in hydrochloric acid, but 254SMO can be used in diluted hydrochloric acid at normal temperature. There is no need to worry about pitting corrosion in the area below the boundary line. But we must try to avoid the existence of cracks. In fluosilicic acid (h2sif4) and hydrofluoric acid (HF), the corrosion resistance range of ordinary stainless steel is very limited, while unss31254 can be applied in a wide range of concentration and temperature.

Related News

Submitted successfully

We will contact you as soon as possible